- Freeze Dryers

- APPLICATIONS

- Laboratory

- Dual Condenser

- About Us

- Contact

- Quality In Freeze Drying

- Quantifying Vial Capping Process - Webinar

- Complex Injectables - Webinar

- Deuterium Exchange - Webinar

- Continuous Lyophilization - Webinar

- COVID-19

- Lyophilized Drug Appearances

- Freeze Dryer Size Calculators

- Legal

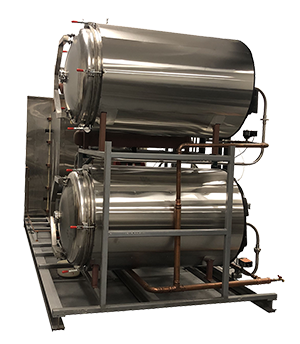

FUTURA PRODUCTION® SERIES

The following specifications are for our standard Futura® 200KG and Futura® 400KG freeze dryers. If you require something different, we can usually custom fabricate your requirements for shelf size and other running specifications.

Please call us at (518) 828-2180 for a needs analysis.

Please call us at (518) 828-2180 for a needs analysis.

|

Futura® Production Specifications:

DIMENSIONS 400KG Machine: APPROX DIMS 96" HIGH x 90" WIDE x 180" F-B 200KG Machine: APPROX DIMS 96" HIGH x 68" WIDE x 153 3/4" F-B PRODUCT CHAMBER 316 L PRODUCT CHAMBER DRAIN W/SHUT OFF VALVE VALIDATION PORT NON-STOPPERING or STOPPERING SHELVES 400 KG Machine: (24) 40" x 60" PRODUCT SHELVES (101.6 cm x 152.4 cm) 400 SQ FT USABLE SHELF AREA 200 KG Machine: (20) 36" X 40" PRODUCT SHELVES (91.44 cm x 101.6 cm) 200 SQ FT USABLE SHELF AREA TEMPERATURE RANGE -50 TO 50C (1) RADIANT SHELF SPACING 2.25" BETWEEN SHELVES NON TOXIC HEAT TRANSFER FLUID PROBES T COUPLE JACK PANEL WITH ONE PRODUCT PROBE PER SHELF (more as needed). ALSO PROBE SHELF IN & OUT AND 2 ICE CONDENSER PROBES REFRIGERATION SYSTEM (1) 30 HP 2 STAGE BITZER 460 3 PHASE (1) 30 HP 2 STAGE BITZER 460 3 PHASE WATER COOLED MAX COND LOW -65C (-80C as needed) SHELF TEMP -50 to 50C CFC FREE REFRIGERANTS DRIP TRAY COMPRESSOR BITZER 30 HP (2) SEMI HERMETIC, FIELD SERVICEABLE VACUMM / VALVES VACUUM PUMP 60 CFM ANTI SUCKL BACK VALVE TWO STAGE CORROSION RESISTANT OIL MIST ELIMINATOR PIRANI VACUUM GAUGE CAPACITANCE MANOMETER PRESSURE BACK-FILL ELECTRIC VBS VALVE MLS 622A 2 TORR RANGE CONDENSER 400KG MACHINE: 316 L ICE CONDENSERS 200 KG CAPACITY EACH 100 KG EACH / 24 HOURS 200KG MACHINE: 316 L ICE CONDENSERS 100 KG CAPACITY EACH 50 KG EACH / 24 HOURS SYSTEM GENERATED HOT WATER DEFROST DOOR / GASKET / CLAMPS STAINLESS STEEL DOOR WITH LIGHTED VIEW PORT IMPROVED SILICONE GASKET STAINLESS STEEL TOGGLE CLAMPS AS HOLD DOWNS ELECTRONICS EATON CONTACTS AND CIRCUIT BREAKERS POWER 208-230 3 PHASE COMPUTERIZATION ADVANCED PC/PLC CONTROL SYSTEM LAPTOP OR DESKTOP AVAILABLE FULLY CONFIGURABLE UNLIMITED RECIPES MANUAL OR AUTO OPERATION AUTOMATIC LEAK RATE TESTING PROGRAMMING REMOTE ACCESS WINDOWS BASED PC BATCHED REPORTS 10 FREEZING STEPS 16 DRYING STEPS AUTOMATIC DEFROST FOOTING 3/14 I BEAM KEY FEATURES SUMMARY DOUBLE DRY® DUAL CONDENSER SEMI CONTINUOUS OPERATION FULL SCREEN GRAPHICS - SHOWS PHASES OF OPERATION UNLIMITED PROGRAM AND DATA STORAGE SEMI HERMETIC COMPRESSOR, FIELD SERVICEABLE TRAYS ARE INCLUDED VACUUM CONTROL VALVE INCLUDED 316L STAINLESS STEEL ON ALL WETTED PARTS |

The FUTURA® PRODUCTION freeze dryers are available with shelf level temperature control or chamber drum configurations.

It is a fully configurable, near continuous operable production system, available with or without stoppering. REQUEST A QUOTE |

|

Ordering and Technical Information

Hudson Valley Lyomac maintains a staff of qualified Field Service Engineers that provide technical assistance for the installation, commissioning, repair, and maintenance of Hudson Valley Lyomac freeze-dryers. Our technical support centers are located in Europe and the US, as well as in key regional Customer Centers worldwide. |

Need Help?

Have a question? Need Our Assistance? Email: [email protected] Call: 518-828-2180 Mailing Address Hudson Valley/Lyomac 793 Route 66 Hudson, NY 12534 USA |

- Freeze Dryers

- APPLICATIONS

- Laboratory

- Dual Condenser

- About Us

- Contact

- Quality In Freeze Drying

- Quantifying Vial Capping Process - Webinar

- Complex Injectables - Webinar

- Deuterium Exchange - Webinar

- Continuous Lyophilization - Webinar

- COVID-19

- Lyophilized Drug Appearances

- Freeze Dryer Size Calculators

- Legal