- Freeze Dryers

- APPLICATIONS

- Laboratory

- Dual Condenser

- About Us

- Contact

- Quality In Freeze Drying

- Quantifying Vial Capping Process - Webinar

- Complex Injectables - Webinar

- Deuterium Exchange - Webinar

- Continuous Lyophilization - Webinar

- COVID-19

- Lyophilized Drug Appearances

- Freeze Dryer Size Calculators

- Legal

|

FDA Regulations and cGMP Guidelines

Hudson Valley Lyomac freeze dryers help companies meet FDA regulations and cGMP guidelines by offering advanced features such as validated processes, automated control systems, data logging capabilities, and strict adherence to temperature and pressure parameters. This ensures consistent and traceable production, product quality, and compliance with regulatory standards.

|

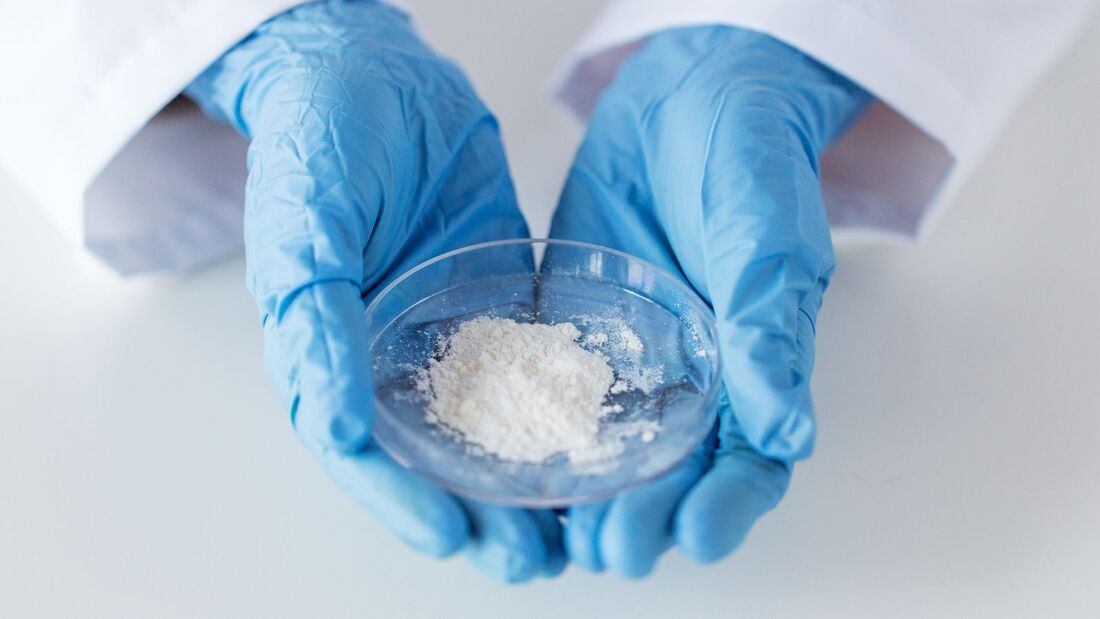

Freeze Drying for API Production

Freeze drying is important for API (Active Pharmaceutical Ingredient) production because it allows for long-term stability, preservation of potency, and easier storage and transportation.

Lyophilizing API helps remove water without damaging the active compounds; this maintains the structural integrity of sensitive molecules, minimizing degradation and chemical reactions, and extending shelf life. Tailored API Solutions

Hudson Valley Lyomac customers rely on our expertise to deliver a tailored freeze drying solution for their API needs. By understanding their specific requirements, offering customization options, providing technical expertise, and delivering reliable equipment, we ensure a seamless integration of freeze drying processes into their API production workflows.

|

Fill out the form below to speak with an expert.

Get in touch for more information or to get a free quote. Someone from our team will reach out.

Hudson Valley Lyomac maintains a staff of qualified Field Service Engineers that provide technical assistance for the installation, commissioning, repair, and maintenance of Hudson Valley Lyomac freeze-dryers. Our technical support centers are located in Europe and the US, as well as in key regional Customer Centers worldwide.

|

Ordering and Technical Information

Hudson Valley Lyomac maintains a staff of qualified Field Service Engineers that provide technical assistance for the installation, commissioning, repair, and maintenance of Hudson Valley Lyomac freeze-dryers. Our technical support centers are located in Europe and the US, as well as in key regional Customer Centers worldwide. |

Need Help?

Have a question? Need Our Assistance? Email: [email protected] Call: 518-828-2180 Mailing Address Hudson Valley/Lyomac 793 Route 66 Hudson, NY 12534 USA |

- Freeze Dryers

- APPLICATIONS

- Laboratory

- Dual Condenser

- About Us

- Contact

- Quality In Freeze Drying

- Quantifying Vial Capping Process - Webinar

- Complex Injectables - Webinar

- Deuterium Exchange - Webinar

- Continuous Lyophilization - Webinar

- COVID-19

- Lyophilized Drug Appearances

- Freeze Dryer Size Calculators

- Legal